Hey, everybody!

Now let’s share with you the raw material of dies, carbon steel, what it is.

The paper cutting dies are very hard and can cut paper 700 to 900 times without being damaged. How does it do this? The key is the use of carbon steel.

Mainly refers to the mechanical properties depend on the carbon content of the steel, and generally do not add a large number of alloying elements of steel, sometimes also known as plain-carbon steel or carbon steel.

Carbon steel, also called carbon steel, refers to an iron-carbon alloy with a carbon content of WC less than 2%.

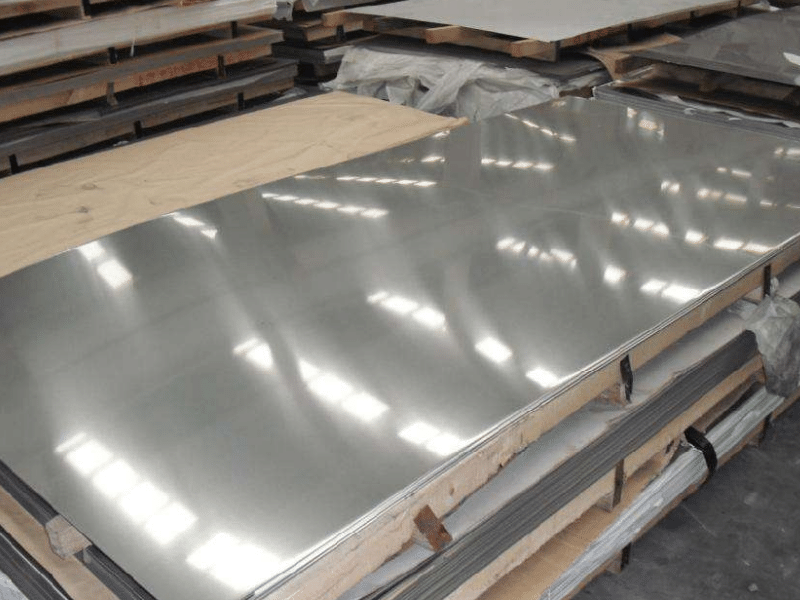

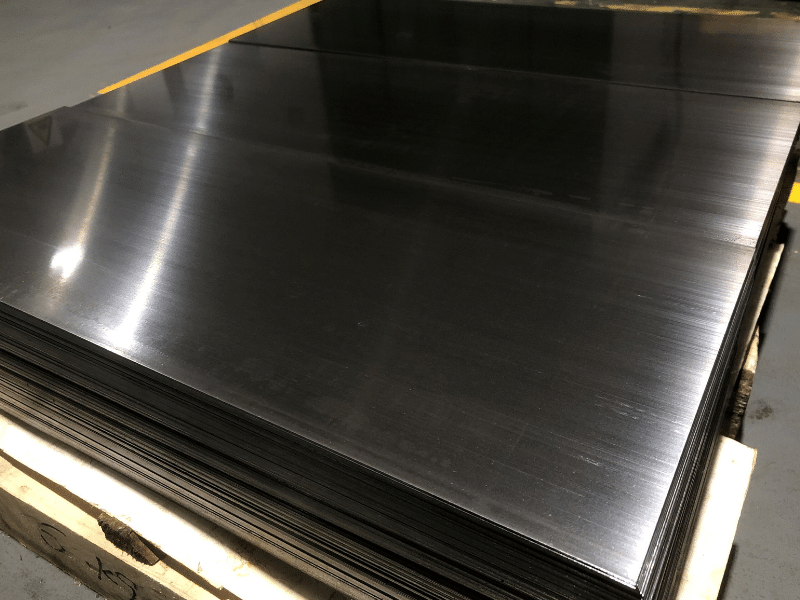

Why don’t we use stainless steel as raw material? Stainless steel contains more chromium and nickel metal, and its exterior color is mostly silver bright color. Carbon steel is mainly carbon and iron alloy, other metal elements are less, the appearance of the main color is the color of iron, the color will be much darker. Carbon steel surface with magnetic can be magnet adsorption. Stainless steel is not magnetic under normal circumstances, and will not be magnetized.

Some customers’ paper cutting dies will be attached to the adhesive magnet as a way of packaging, so carbon steel can do this very well.

When we create art, dies to need to be cut back and forth many times, so we need to have rigid materials to meet our needs.

Generally speaking, the higher the carbon content in carbon steel, the greater the hardness and strength, which can help us complete the desired work.

After the carbon steel is etched, the sharpness of the blade can fully meet the export standards of Europe and the United States and can well cut the paper to make the work appear.

The carbon steel material we choose is in line with environmental standards and promotes ecological development, so it is the first choice.